Automatic Chocolate Depositing Line HTL-TI/TII/TIII

Automatic Chocolate Depositing Line HTL-TI/TII/TIII

Location:Germany

Available quantity:99

Description

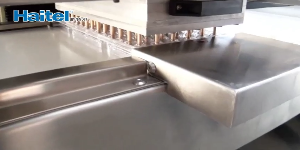

HTL-I / HTL-II / HTL-III Automatic Chocolate Pouring Production Line

Product Description

The HTL series automatic chocolate pouring machines are high-performance production systems designed to automate the full chocolate forming cycle—template baking, precise pouring, tapping, and cooling—with exceptional flexibility and output capacity. These machines are ideal for manufacturing a wide range of chocolate varieties, including:

- Plain chocolate

- Two-color (dual-tone) chocolate

- Sandwich-filled chocolates

- Nut-infused chocolates

- Geometrically molded chocolates (over 100 shape types available)

Equipped with high-speed pouring heads, custom mold capabilities, and intelligent control systems, these machines deliver stable performance, high output, and ease of operation for industrial-scale chocolate production.

Key Features

- Versatile Chocolate Forming: Supports a wide variety of chocolate styles, including geometric shapes, layered fillings, and inclusions like nuts or crisped grains.

- Custom Molding Capabilities: Over 100 chocolate shapes supported by default; molds can be customized according to client requirements.

- Automated Production Process: Covers baking, dosing, vibration (tapping), and cooling in one streamlined operation.

- User-Friendly Operation: Easy to operate with strong adaptability to various chocolate product types.

Technical Specifications (Narrative Format)

The HTL-I, HTL-II, and HTL-III models share the same production output capacity of 800 to 2500 kg per 8-hour shift, making them suitable for medium to high-volume chocolate manufacturing environments. All three models support a pouring speed of 10–18 cycles per minute, allowing rapid processing without compromising precision or quality.

The machines are compatible with plain chocolates ranging from 2.5 to 512 grams, and for sandwich chocolates, the filling proportion can range between 15% and 40% of the total weight.

Each unit operates at an optimal temperature of 20–25°C, with the cooling tunnel maintaining a controlled environment of 5–10°C. The cooling capacity is consistent across all models at 21,800 kcal/h, ensuring effective temperature control during chocolate setting.

Power and air requirements vary slightly by model:

- HTL-I consumes 21 kW of electrical power, requires 0.22 m³/min of air at 0.7 MPa, and weighs approximately 5250 kg, with a footprint of 16.7 × 1.21 × 2.5 meters.

- HTL-II and HTL-III are higher-capacity machines, each requiring 30 kW of power. HTL-II needs 0.412 m³/min of air, while HTL-III operates with 0.1925 m³/min, both at 0.7 MPa. These machines weigh 6950 kg and 7450 kg, respectively, with identical dimensions of 19.85 × 1.21 × 2.5 meters.

Summary

The HTL-I, HTL-II, and HTL-III automatic chocolate pouring lines offer robust performance, strong customization capabilities, and reliable long-term operation. Whether producing filled, multi-color, or uniquely shaped chocolates, this system ensures precision, consistency, and high output—making it an ideal investment for industrial chocolate manufacturers.

Specifications

| Manufacturer | GLOBAL TECHNICAL SOLUTIONS |

| Model | HTL-I |

| Year | 2025 |

| Condition | New |

| Stock Number | . |