SCZM-200-1650 Cotton Towel Full Automatic V Folding Machine

SCZM-200-1650 Cotton Towel Full Automatic V Folding Machine

Location:Germany

Available quantity:99

or

Call +971 58 579 4328

Description

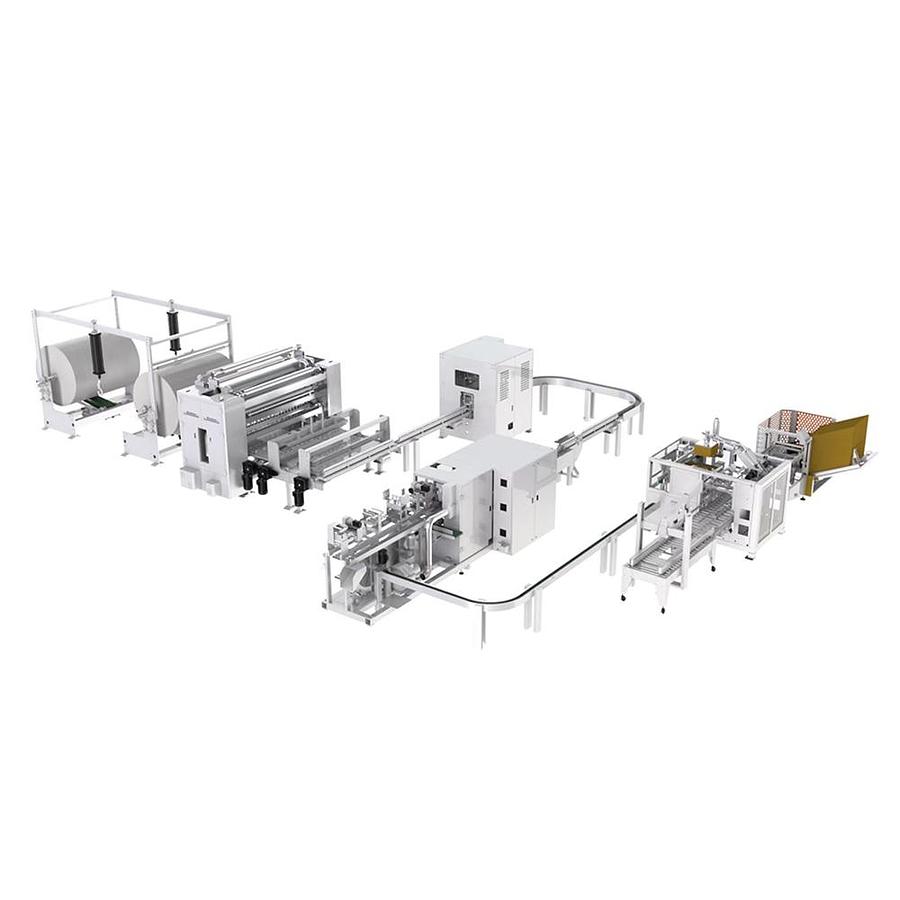

SCZM-200-1650 Folding and Stacking Production Line

A high-speed, fully automated production system designed for nonwoven cotton, adhesive, polyester, and similar materials. The line integrates jumbo roll unwinding, folding, stacking, shaping, and pushing-out systems to ensure precise, stable, and high-capacity operation.

Main Technical Parameters

- Design Speed: 100 m/min

- Stable Speed: 80 m/min (≈ 8–10 logs/min)

- Max. Jumbo Roll Width: 1650 mm

- Specification (Folding Width): 200 mm (customizable)

- Raw Material: Nonwoven fabrics (cotton, adhesive, polyester, sticky polyester)

- Ply: Single layer, 40–100 g/㎡

- Optimum Effective Material Widths: 1632–1650, 1600–1610, 1560–1578, 1518–1546, 1485–1505 mm

- Noise Level: ≤85 dB

- Power Supply: 380V, 50Hz, 3-phase

- Total Installed Power: ~59.1 kW

Main Sections & Features

1. Back Stands (SCZM-200-1650)

- Max roll width: 1650 mm, diameter ≤ φ1500 mm, weight ≤ 0.4T

- Axial type roll fixing with single belt system

- Manual edge alignment and web threading

- Tension controlled via touch screen

- Equipped with cloth break detection and auto-stop

- Power: 1.5 kW × 2 = 3 kW

- Weight: ~540 kg

2. Folding Part (SCZM-200-1650)

- Folding speed: 80 m/min (5–8 logs/min)

- Folding width: 200 ± 2 mm

- Final folded size: 100 (+1, +4) mm

- Folding type: Vacuum adsorption, staggered “V” folding

- Spiral cutter with cloth-connecting processing

- Vacuum power: 37 kW pump

- Driving power: 5.5 kW motor

- Structure: Wall plate frame, CNC-machined aluminum alloy parts

- Weight: ~3200 kg

3. Automatic Stacking (SCDM-200-1650)

- Servo-motor independent stacking system

- Set stack count via touch screen (100% accurate)

- Semi-finished stack height: 200–400 mm

- Max folding logs: 8

- Servo motor power: 9 kW

- Weight: ~1300 kg

- Pneumatics: Airtac components, pressure ≥0.6 MPa

4. Press Cloth Shaping System

- Pneumatic pressurization with anti-static conveyor belts

- Independent frequency converter drive

- Equipped with photoelectric detection to avoid collisions

- Pressing height: 20–150 mm

- Power: 0.75 kW

- Weight: ~320 kg

5. Pushing-Out System

- Anti-static conveyor belts with cylinder + guide rail press

- Servo start/stop with photoelectric safety detection

- Power: 0.75 kW

- Weight: ~220 kg

Motor Power List (Reference)

- Vacuum pump motor: 37 kW × 1

- Folding main motor: 5.5 kW × 1

- Cloth feed motors: 1.5 kW × 2 = 3 kW

- Jaw lifting & moving servo motors: 2–1 kW each

- Conveyor belt motors: 0.25 kW × 2

- Correction group motors (optional): 0.55 kW × 2

- Total Power: 59.1 kW

Capacity Calculation (Example)

- Material: 60 gsm, 1 layer, 1650 mm width

- Efficiency: 75%

- Speed: 100 m/min

- Production time: 8 h

- Daily Production: ≈ 7.12 tons

Quality Guarantee & Acceptance

- Cross-cutting size: 200 ± 2 mm

- Folding size: 100 (+1, +4) mm

- Longitudinal tolerance: ±2 mm

- Qualified product rate: ≥98%

- Clean folding, no wrinkles, defects, oil, or damage

- Continuous 4h acceptance test with stable output at ≥80 m/min

Workshop Requirements

- Humidity: 45–65% RH

- Air source: 0.6 MPa, Ø12 mm pipe

- Vacuum: –250 to –350 mmHg, 42.56 m³/min

- Power bus: 35 sq. mm wire + 16 sq. mm ground/neutral

- Air duct: φ200 mm PVC

Free Spare Parts

- Breaking knife ×1

- Cutting knife ×2

- Buckles ×6

- High-temperature tape ×1 roll

- Toolbox ×1 set

- Blower air gun, vise, scissors, wrench set, Allen wrench set

- Emergency stop button (Schneider) ×1

- Relay, photoelectric & proximity sensors, thermal relay, circuit breakers

System Configuration

- SCZM-200-1650 Back Stands – 2 sets

- SCZP-1650 Deviation Correcting Device – 1 set (optional)

- SCZM-200-1650 Folding Part – 1 set

- SCZM-200-1650 Automatic Stacking – 1 set

- SCZM-1650 Logs Accumulator – 1 set (optional)

Specifications

| Manufacturer | GLOBAL TECHNICAL SOLUTIONS |

| Year | 2025 |

| Condition | New |

| Stock Number | . |