WFR1500+WL1520D High-Speed Floder With Alignment System

WFR1500+WL1520D High-Speed Floder With Alignment System

Location:Germany

Available quantity:99

or

Call +971 58 579 4328

Description

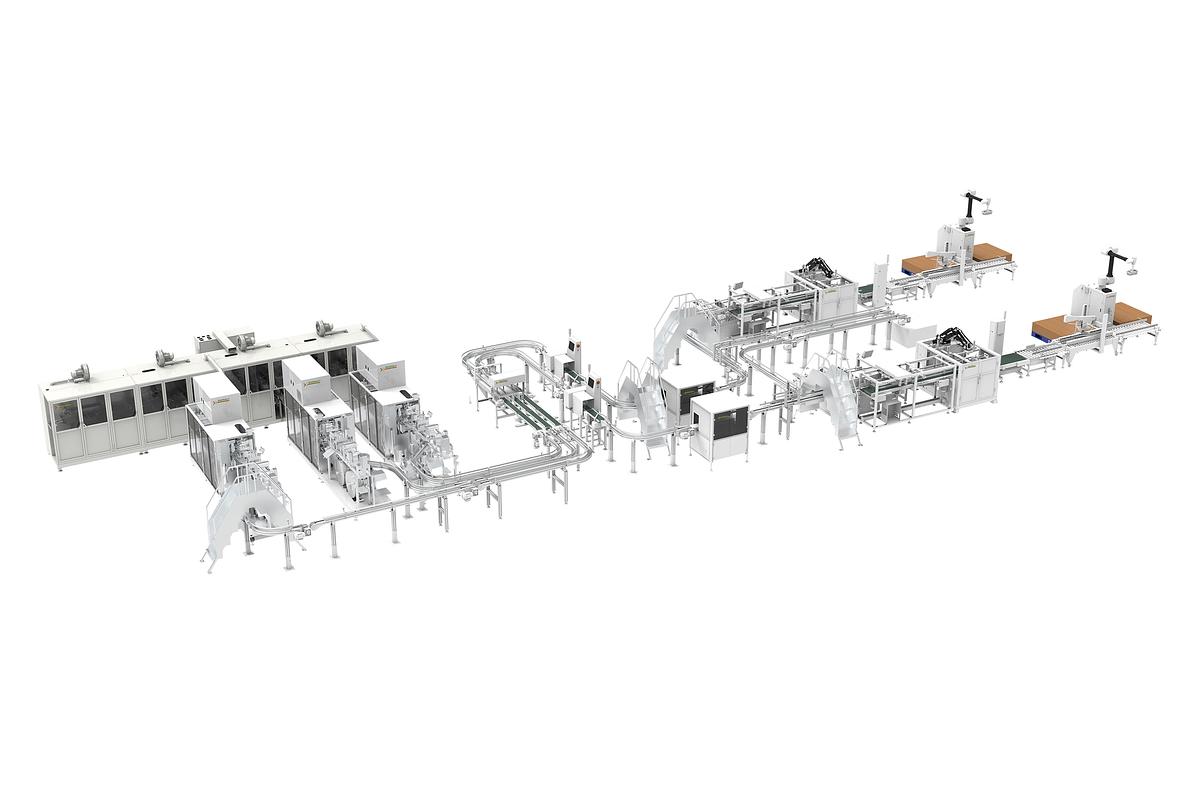

Sanitary Napkin Stacking & Automatic Boxing System

Model: WFR1500 + WL1520D

Device Working Principle

This system is designed for stacking sanitary napkins and seamlessly connecting with automatic boxing machines to perform E1/E2/F1/F2 box-loading modes.

- Products are conveyed from the production line to the stacking unit via conveyor belt.

- The system automatically completes single-pack stacking and pushes them into the boxing machine.

- Controlled by a full-servo transmission and PLC system, ensuring stable, accurate, and efficient operation.

Main Technical Parameters

- Equipment Model: WFR1500 + WL1520D

- Max. Stacking Speed: 1200 pcs/min

- Stacking Specification: 16–40 pcs/push (aligned with boxing machine capacity)

- Compatible Packaging Speed: 30–65 packs/min

- Total Power: 65 kW (subject to actual conditions)

- Power Supply: 380V ±10%, 50Hz ±5% (Control Voltage: DC 24V)

- Dimensions (L×W×H): 5700 × 1400 × 2000 mm (subject to actual conditions)

- Equipment Weight: ~4500 kg

- Noise Level: ≤85 dB

- Color: RAL7035 (customizable)

Main Configurations

Mechanical Part

- Belt conveyor unit

- Synchronous belt drive unit

- 90° rotation unit

- Servo blocking unit

- Servo feeding unit

- Air wheel feeding unit

- Waste discharge unit

Electrical Part

- PLC system, touch screen, servo motors, sensors

- Pneumatic system with pressure gauges at each point

- Clearly labeled solenoid valves for easy maintenance

Core Functions

- Belt Conveyor Unit – Upper/lower belt clamping, servo-driven, speed synchronized with main machine.

- Synchronous Belt Drive Unit – Imported 8M belt, servo-driven, precise and reliable.

- 90° Rotation Unit – Negative pressure suction conveyance, high-precision phase detection, stable cam operation.

- Servo Blocking Unit – Direct servo drive, precise, efficient, and responsive.

- Servo Feeding Unit – Dual servo groups, automatic adjustment for phase differences, higher efficiency.

- Air Wheel Feeding Unit – Dual air-wheel feeders for continuous, stable operation.

- Waste Discharge Unit – Automatic removal, servo-controlled belt output.

Safety & Reliability Features

- Overload protection with automatic shutdown and manual reset.

- Emergency stop button halts all operations instantly.

- Planetary gearbox + servo motors with high-temp and overload alarms.

- Safety doors with magnetic/latch locks and interlock switches (machine alarms and stops when opened).

- Cabling and wiring meet GB standards; maintenance-friendly design with rear access electrical cabinet.

General Standard Parts List

Special Tools

- Equipment Manual – 1 book

- Certificate of Conformity – 1 piece

- Warranty Card – 1 piece

- Tool Set – 1 set

Main Configuration Components

- Servo Motor – Mitsubishi (Japan)

- Servo Driver – Mitsubishi (Japan)

- PLC – Mitsubishi (Japan)

- Inverter – Mitsubishi (Japan)

- Power Module – Mitsubishi (Japan)

- Photoelectric Switch – Keyence (Japan)

- Proximity Switch – Huichuan (China)

- Pneumatic Components – SMC (Japan)

- Touch Screen (HMI) – Mitsubishi (Japan)

- Intermediate Relay – Schneider (France)

- Relay Base – Schneider (France)

- Rotary Encoder – Omron (Japan)

- AC Contactor – Schneider (France)

- Air Switch – Schneider (France)

- Emergency Stop Button – Schneider (France)

- Safety Door Switch – Omron (Japan)

- Motor Protector Aux. Contacts – Schneider (France)

- Motor Protector – Schneider (France)

- Solenoid Valve – Airtac (Taiwan)

- Linear Guide/Slider – Shinyi (Taiwan)

- Bearings – NSK (Japan)

- Gearbox – Shinba (Japan)

- Fan – Yunfeng (China)

- Flat Belt – Habasit (Switzerland)

- Timing Belt – Gates (USA)

Specifications

| Manufacturer | GLOBAL TECHNICAL SOLUTIONS |

| Year | 2025 |

| Condition | New |

| Stock Number | . |