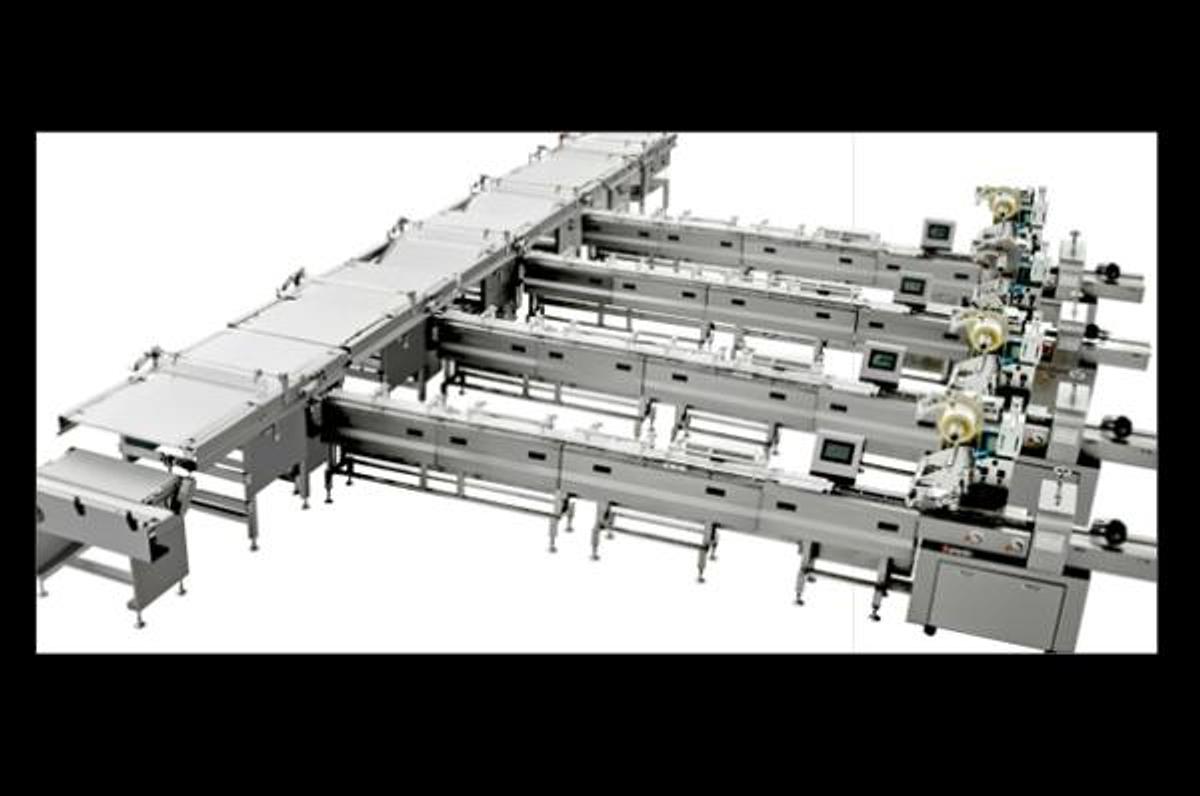

Automatic Sorting Pillow Packing Line

Automatic Sorting Pillow Packing Line

Location:Germany

Available quantity:99

or

Call +971 58 579 4328

Description

Automatic Sorting System

- Optimized for Aligned Products

- Designed for items arranged in neat rows, ensuring precise and efficient sorting.

- Automatic Stop Function

- Integrated auto-stop mechanism enhances operational safety and efficiency.

- Quick Belt Removal

- The conveyor belt can be easily disassembled and reassembled without tools, reducing maintenance time.

- User-Friendly Design

- Streamlined receiving and turning structure facilitates smooth product infeed and outfeed.

- Safety Features

- Equipped with an anti-pinch protection system for operator safety.

- Optional Pneumatic Correction

- A pneumatic deviation correction unit can be added to enhance belt alignment accuracy.

- Smart Integration

- Supports automatic distribution and conversion based on the real-time status of the feeding and packaging line.

Automatic Feeding System

- High-Speed & Precision

- Delivers stable, high-speed performance with accurate positioning for consistent feeding.

- Easy Product Changeover

- Quick and intuitive setup for different product sizes or specifications.

- Tool-Free Maintenance

- The conveyor belt can be removed easily without the need for tools.

- Hygienic & Safe Design

- Simple, clean structure built for food-grade environments.

Packaging Machine Advantages

- Optional Auto Film Docking

- Reduces downtime with automatic membrane connection features.

- High Performance

- Combines speed, stability, and precision, ideal for large-scale production.

- Reliable Components

- Built with high-quality original parts for long-term performance and low maintenance.

Application Scope

This integrated system is ideal for use in automated food packaging lines, including:

- Shaqima

- Biscuits

- Bread

- Cakes

- Peanut candy

- Chocolate bars

- Wafer biscuits

- And other similar solid food products

1. Sinking Unit

- Function: Designed to lower products gently and uniformly for subsequent processing or alignment stages.

- Power: 0.75 kW

- Band Width: 900 mm

- Dimensions: 1900 × 1300 × 1200 mm

2. Uniform Unit

- Function: Aligns and equalizes product spacing for consistent downstream feeding.

- Power: 0.75 kW

- Band Width: 900 mm

- Dimensions: 1300 × 1300 × 1200 mm

3. Finishing Unit

- Function: Final product correction or touch-up stage before packing.

- Power: 1.5 kW

- Dimensions: 980 × 170 × 800 mm

4. Logic Unit

- Function: Centralized control and logic coordination between units, ensuring real-time synchronization.

- Power: 3.0 kW

- Dimensions: 1940 × 500 × 800 mm

5. Packaging Machine

- Function: Final wrapping and sealing of products, compatible with a variety of solid food items.

- Power: 3.0 kW

- Dimensions: 1400 × 1370 × 850 mm

6. Discharge Motor

- Power: 0.32 kW

Electrical Requirements

- Voltage: 3-phase, 380V

Specifications

| Manufacturer | GLOBAL TECHNICAL SOLUTIONS |

| Year | 2025 |

| Condition | New |

| Stock Number | . |