Thermoforming Machine for Food

Thermoforming Machine for Food

Location:Germany

Available quantity:99

Description

THERA 650

Machine frame in AISI 304 stainless steel, suitable for clean rooms or aggressive environments

Modular frame, which can be adjusted and manufactured according to specific customer requests (integration with additional devices, increasing the length of the loading area) or production needs (“left-right” machine).

Standard components (FESTO, BUSCH, SIEMENS) for better spare parts management.

Forming through the vacuum process, with (pre)heating plates and plugs (traditional or heated, when necessary).

Forming molds designed according to the product characteristics and the customer's request (dedicated shape, logo, grooved sides, easy opening)

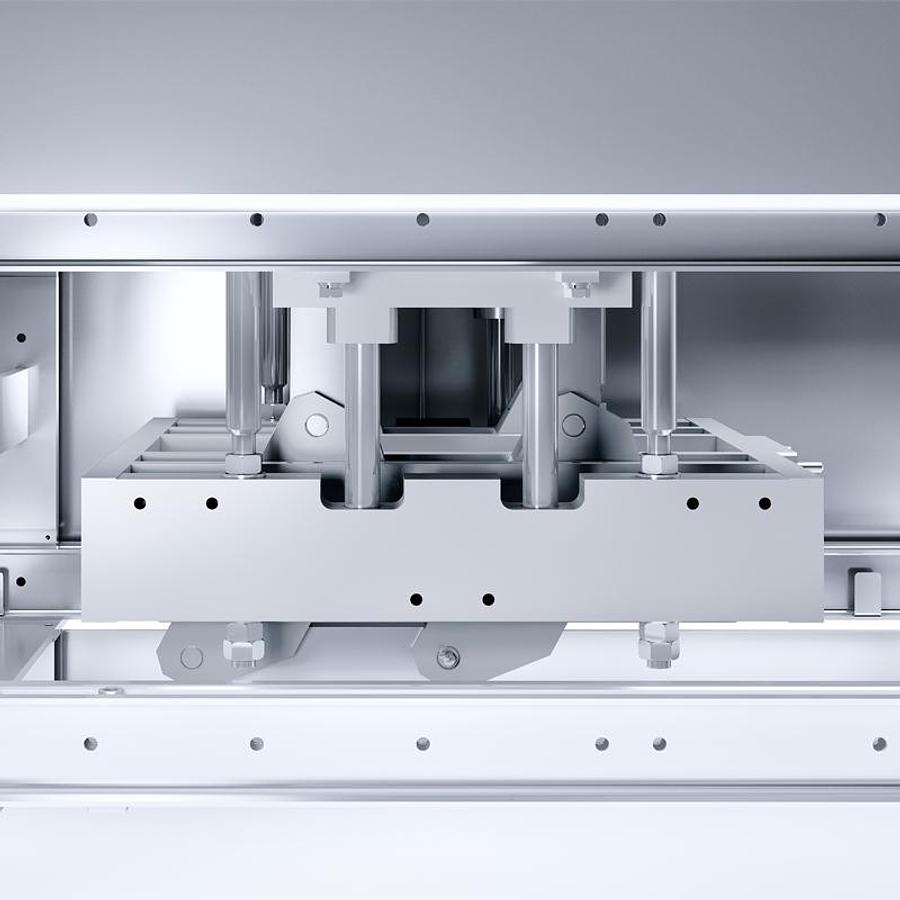

Quick and easy change of mold configuration, where no tools are required thanks to the assisted system for opening the upper chamber and direct access to the molds

Dedicated cutting systems, made according to the number of packages, their characteristics, material thickness and to ensure long-lasting blade efficiency.

Optionally available: CFR 21, an integrated quality control and software technology, to improve process and product traceability

Loading area accessible from both sides and with the possibility of an open frame to allow seated operator positioning

Installation of different indexes, thanks to the easy system for changing the upper chamber or with the machine in the FV version ("Variable Format" - which means Adjustable Index), with the installation on the machine frame of 2 forming chambers and 2 sealing chambers with different indexes

The same machine can be used to form rigid or flexible packages, with or without modified atmosphere or vacuum packages.

Machine integration with automatic loaders (dedicated loading systems, dosing systems, denesters), downstream devices (labeling machines, checkweighers, cartoning machines, alignment systems) and automatic data printing systems.

Easy line management via the touch screen control panel and dedicated software for modifying and studying machine parameters

integral cutting system

POSIFORM training cycle available

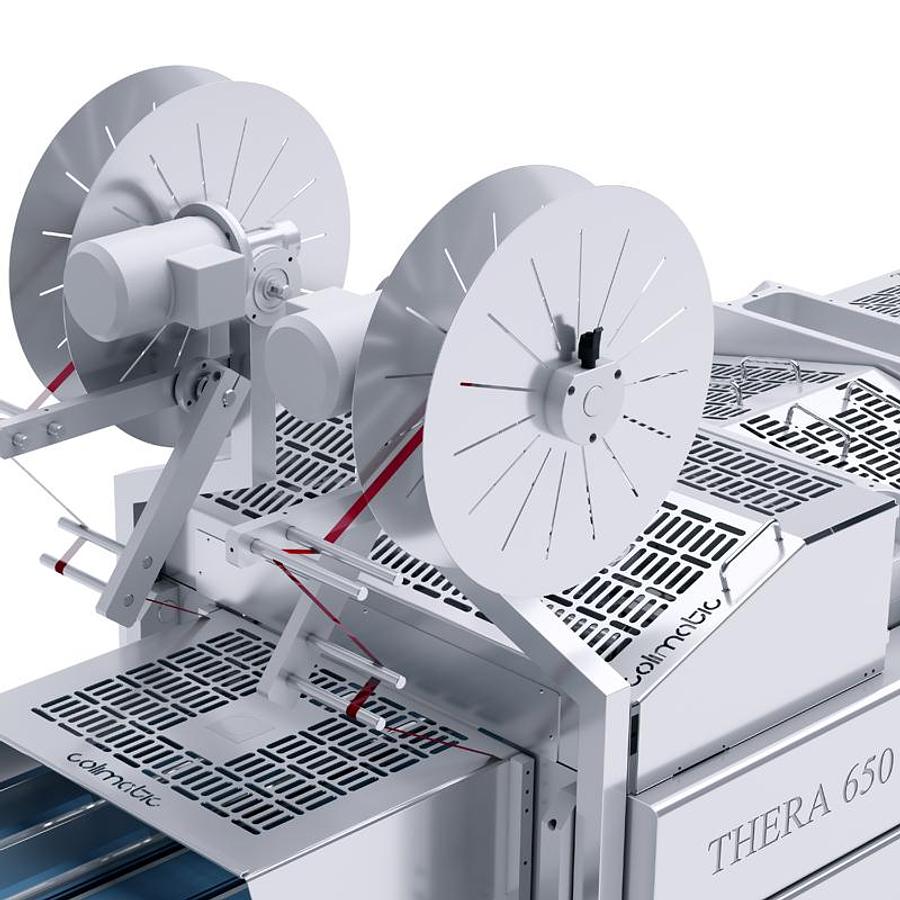

Special conveyor chain for the upper shrink films, to facilitate their entry and perfect sealing in the sealing chamber with servomotors for unwinding the chain and the film with tension device and oscillating arm, web end detector

Specifications

| Year | 2025 |

| Condition | New |

| Stock Number | . |