Cheese Production Plants | Hard, Semi-Hard and Soft Cheese Processing Lines

Cheese Production Plants | Hard, Semi-Hard and Soft Cheese Processing Lines

Location:Germany

Available quantity:99

Description

Cheese Production Plants – Hard, Semi-Hard and Soft Cheese Processing Lines

The cheese production plants by BISIGNANO are engineered to meet the highest standards of quality, efficiency, and international competitiveness. Designed for the production of hard, semi-hard, and soft cheeses, these plants offer flexible configurations and advanced automation levels to support professional dairy operations of all sizes.

The high level of automation and mechanization integrated into these systems ensures excellent processing performance, consistent product quality, and optimized production workflows. Each plant is custom-designed according to the required production capacity, cheese type, and operational preferences, allowing precise control over every stage of the cheese-making process.

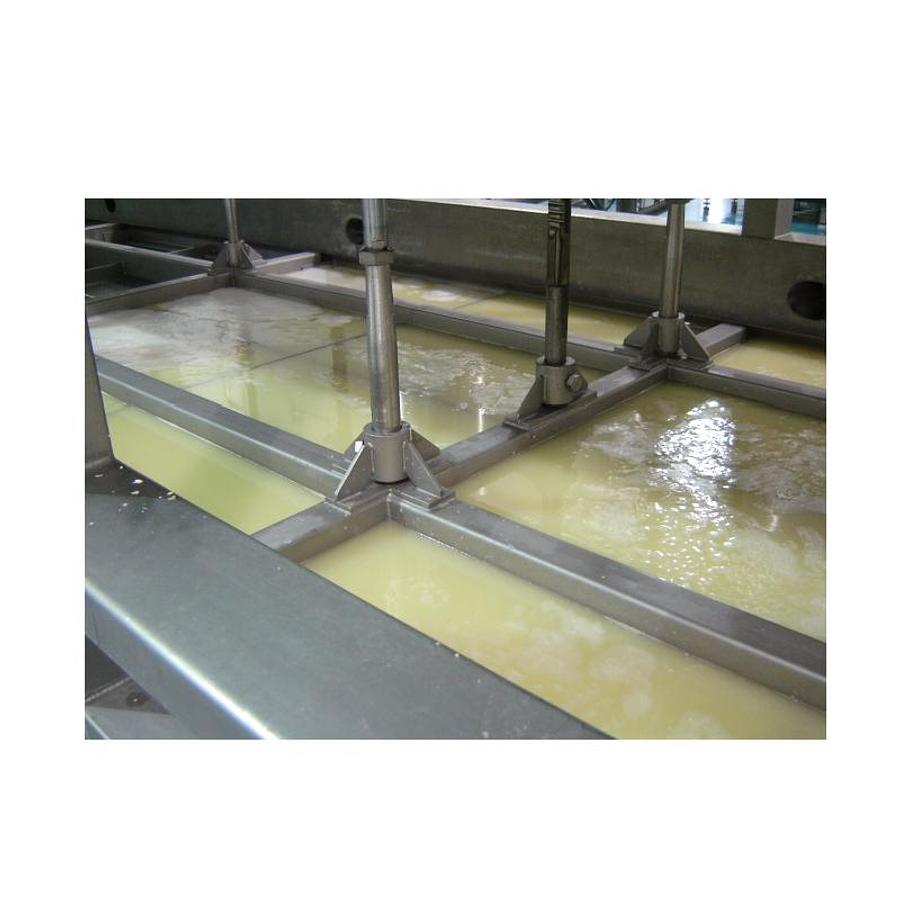

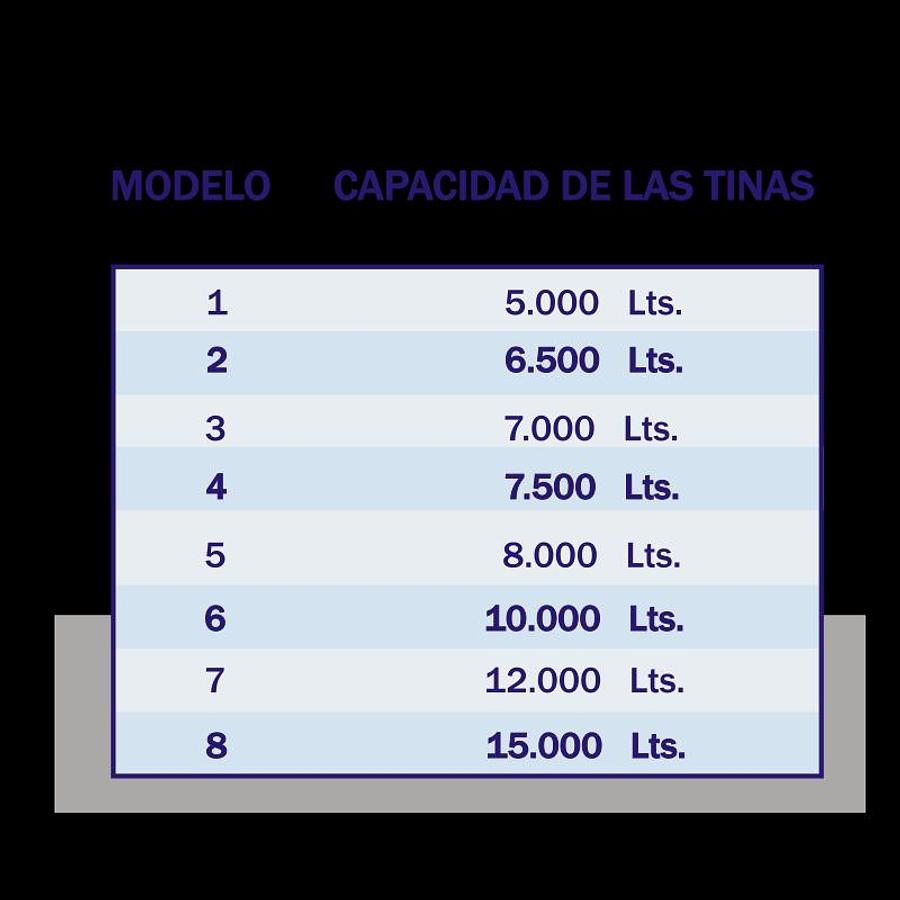

Pasteurization systems include plate pasteurizers suitable for various applications and temperature ranges, ensuring safe and controlled milk treatment. Cheese vats are available in different capacities, with open or closed designs, manual or fully automated operation, and specialized bottom configurations such as double-O, double conical, or flat-bottom designs. All vats are built according to sanitary design standards and equipped with pneumatic discharge valves, making them suitable for curd production for multiple cheese varieties.

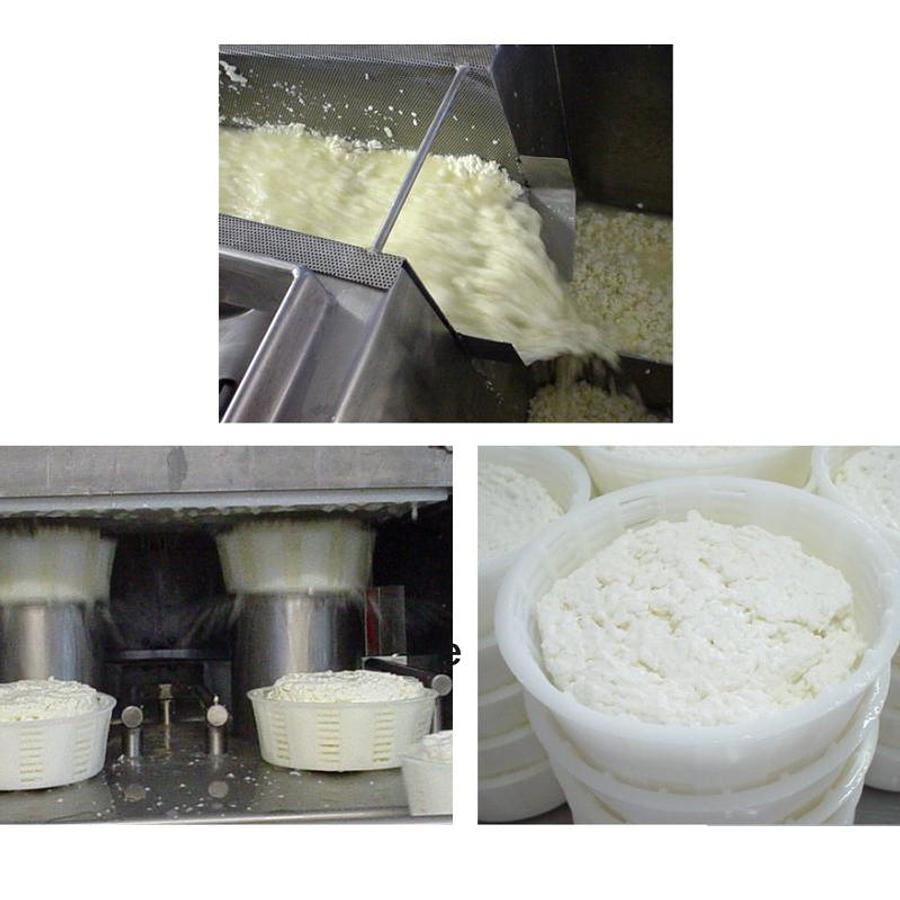

Pressing systems are available in vertical or horizontal configurations, with mechanical or pneumatic operation. Options with air cushions are available for integration into automatic production lines. Dewatering solutions include manual pneumatic pre-pressing trays and fully automatic moving-bottom drainers equipped with micro-perforated belts for efficient whey removal.

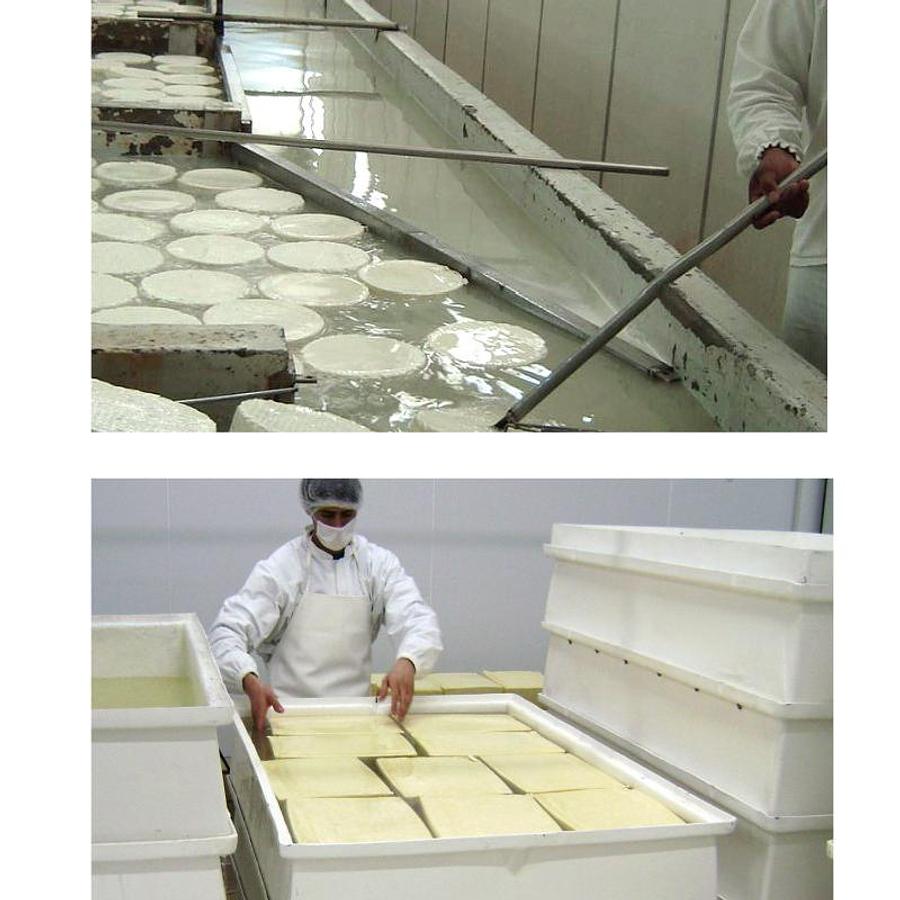

Salting houses are designed as complete systems, offering plastic or stainless steel tubs, semi-deep salting tanks with trays, deep salting pits with overhead cranes, and fully automatic deep salting tanks. Integrated brine handling, filtration, and cooling systems ensure consistent salting conditions for different cheese types.

Molding systems include automatic column mold filling solutions, along with mold transport and conditioning systems to ensure efficient and uniform cheese shaping. Mold and tray washers are fully constructed from stainless steel and include dedicated zones for loading, pre-washing, washing with cleaning solution, final rinsing, and unloading, ensuring thorough sanitation and compliance with hygiene standards.

Main components and processing sections

• Plate pasteurizers for milk treatment

• Cheese vats with various capacities and configurations

• Mechanical and pneumatic cheese presses

• Dewatering and whey drainage systems

• Comprehensive salting house solutions

• Automatic molding and mold handling systems

• Stainless steel mold and tray washing machines

Typical applications

• Production of hard cheeses

• Production of semi-hard cheeses

• Production of soft cheeses

• Industrial and artisan dairy processing

Specifications

| Manufacturer | BISIGNANO |

| Model | Cheese Production Plants |

| Year | 2025 |

| Condition | New |

| Stock Number | STK-BISIGNANO-CHEESE-PRODUCTION-PLANTS-2025 |